Kitting Solutions for Faster, More Accurate Assembly

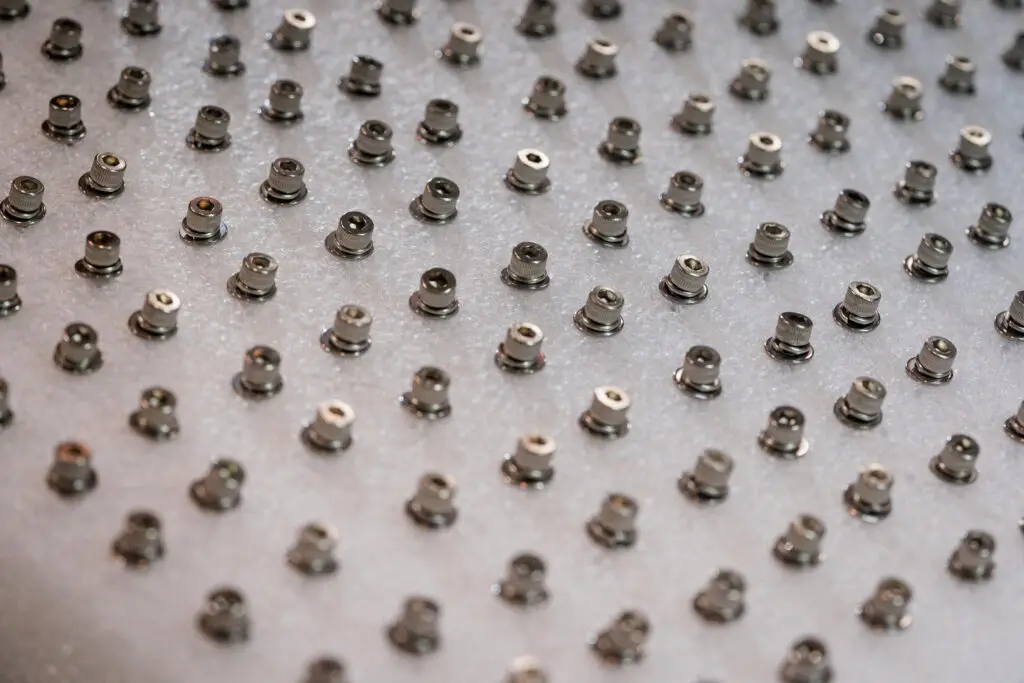

At Specialty Bolt & Screw, our kitting solutions bring together all the components you need for assembly into one organized and clearly labeled package, whether that’s a simple bag or a compartment box with dozens of components. Every kit is built to your specifications to save you time, reduce errors, and keep your production line moving.

Kitting Services Overview

Every Kit Includes:

- Custom component maps showing part names, part numbers, and quantities

- Clear labeling for quick identification

- Secure packaging to protect components in transit

- Flexible configurations, from small bags to multi-part kits

Examples of What We Provide:

- Single-part bagging for one-off or repetitive use

- Multi-compartment kits for complete assembly stations

- Grouped fastener sets for specialized projects

- Maintenance or repair kits for quick field work

What We Offer

How Our Kitting Process Works

Our kitting solutions streamline your supply chain by packaging all required components into custom kits, tailored to your exact assembly needs. Each kit is clearly labeled with part numbers and quantities, helping your team boost productivity and reduce downtime on the production floor.

1. Component Review

We work with you to review your BOM and production workflow to identify where kitting will save you time and money. We identify parts needed, quantities, and special packaging requirements.

2. Custom Kit Design

We design your kit layout to match your assembly process, whether it's a simple labeled bag or a multi-compartment box with a component map.

3. Accurate Assembly

Our team hand-packs each kit, verifying part counts and configurations to ensure consistency across every unit.

4. Labeling & Mapping

Each kit includes clear labeling and a custom component map so your team knows what's included and where it's located,.

5. Delivery & Integration

Kits are delivered to your facility organized, labeled, and ready to use—saving you time, reducing waste, and minimizing production delays.

Discover the SBS Advantage in Kitting Solutions

Reduced Assembly Time

All necessary fasteners and components are organized and ready to use, eliminating the time spent gathering individual parts.

Fewer Production Delays

With every part in its place, the risk of line shutdowns due to missing components is greatly reduced.

Lower Labor Costs

Employees spend less time searching for parts or preparing assembly materials, allowing them to focus on higher-value tasks.

Streamlined Inventory Management

Kits are pre-counted and labeled with part names, part numbers, and quantities, reducing errors and simplifying stock control.

Improved Accuracy

Custom component maps ensure the right parts are included in the right quantities, minimizing assembly mistakes.

Easier Training for New Staff

Clearly labeled kits make it simple for new team members to identify and use the correct parts without extensive training.

Flexible Packaging Options

From small labeled bags to multi-compartment kits, packaging is tailored to your workflow and environment.

Faster Field Service & Repair

Pre-assembled kits means technicians have exactly what they need on-site, reducing down time in the field.

Case Study

Cutting Assembly Prep by 40%

Customer: Mid-size OEM in industrial equipment manufacturing

Challenge: Production team spent hours pulling and staging parts for each assembly.

SBS Solution: We developed custom multi-compartment kits with clearly labeled sections and a printed component map showing part numbers, descriptions, and quantities.

Result:

- Assembly prep time reduced by 40%

- Errors and part shortages eliminated

- Over $50,000 in annual labor savings

Get Started with Kitting Solutions from Specialty Bolt

Ready to simply your assembly process and reduce production delays? SBS offers scalable kitting solutions designed to improve operational efficiency, cut labor costs, and elimate part shortages. Whether you need individually bagged fasteners or full mapped custom kits, our team will tailor a kitting program to fit your exact needs.